Silage Facer

- More Consistent Feed

- Better feed = more milk

- Makes a safer silage face

- Minimal maintenance direct drive system

- Silage pile face remains stabilized

Silage facers are popular in the dairy industry. They lower the risk of oxygen entering the silo bunker face compared to bucketing the feed directly off the silage bunk face.

The biggest reason for buying a silage facer.

Hot weather silage molding is the biggest reason farms switch from bucketing to using a silage defacer. If you have problems with heated silage in the bunk, facing off the silage daily, fixes silage fracture issues.

Improved feed quality leads to increased milk production and better cow health. Don’t lose money from heated silage. Eliminate feed quality issues whenever possible.

Request A Quote

Provide us with a little information and we will get back to you with a quote.

Silage facer design

Hoover’s first design used chains to drive the drum. It didn’t take real long to figure out the chains were an unhandy maintenance issue, and he designed a hydraulic direct drive system.

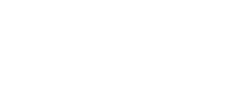

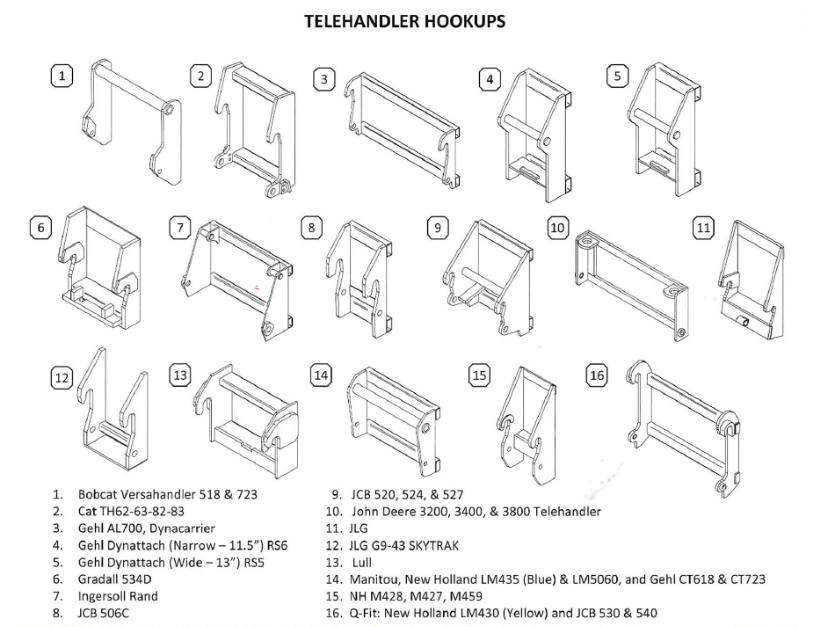

The direct drive system is the most popular and is available in 2 styles. Payloader and skid loader.

Payloader versus skid loader defacer models

The payloader silage facer models are built to handle side stress. Since payloaders swing as they steer, zoned-out employees can side knock the bunker walls. We build the payloader units to take a severe battering from the sides.

The skidloader bunker facers are built to handle the stresses skid loaders give them without weighing too much.

Silage Rakes

Silage rakes work. However, they make it harder to take a small amount off the bunk face than our rotary units. Stay with the rotary silage facer style for the smoothest feed surface, which gives the least oxygen penetration.

Silage facer versus silage defacer

It’s a terminology thing. Some dairymen call them silage defacers; others know them as facers or bunker facers. It’s all the same, and your cows will appreciate you in the hot weather regardless.